How to Increase Throughput with the Right Strapping Machine

How to Increase Throughput with the Right Strapping Machine

Blog Article

Letting loose the Possible of a Strapping Equipment in Simplifying Your Operations

If you're wanting to boost your product packaging performance, a strapping equipment could be the answer you've been browsing for. These makers can reduce manual work while guaranteeing your products are firmly packaged. With various alternatives offered, finding the appropriate fit for your procedures is essential. How do you select the ideal one, and what advantages can you truly anticipate? Let's check out the opportunities together.

Recognizing the Fundamentals of Strapping Machines

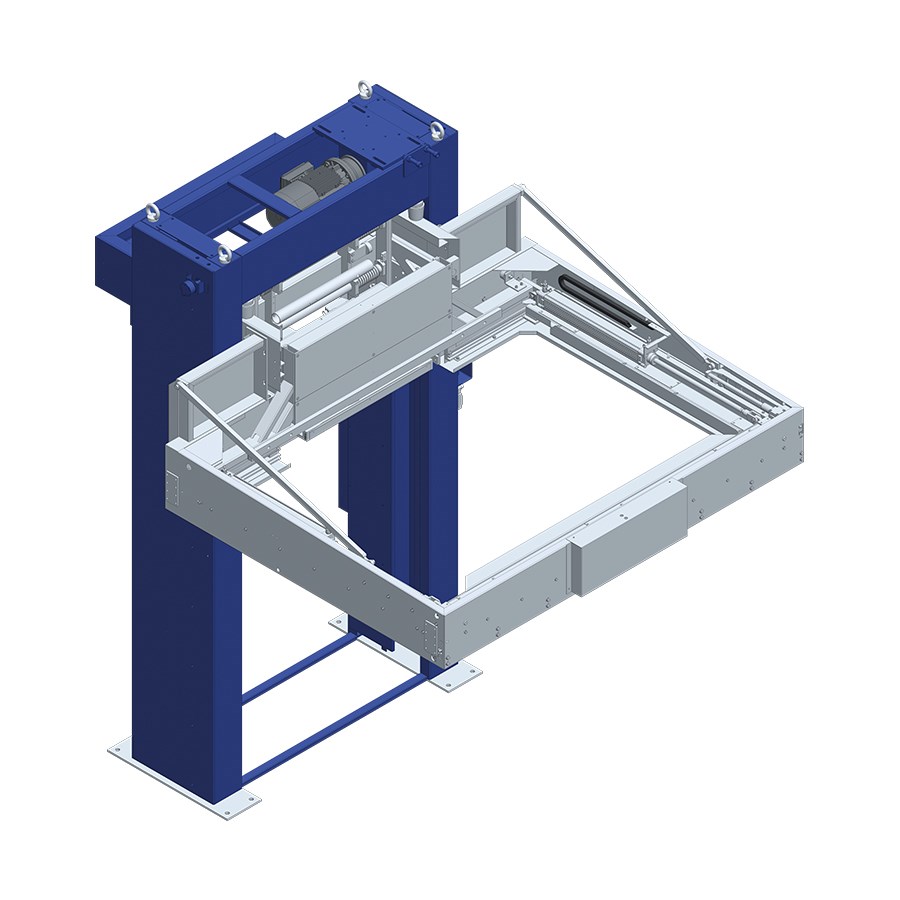

Strapping equipments are necessary tools in product packaging and logistics, made to protect products for risk-free transportation. These machines use numerous materials, like polypropylene or polyester bands, to bundle products with each other (Strapping Machine). You'll find that strapping machines been available in different kinds, consisting of guidebook, semi-automatic, and completely automatic designs, each suited for particular functional needs.Understanding exactly how these makers work is essential for maximizing your operations. They use tension to the strap prior to sealing it, ensuring a limited fit that keeps your products protect throughout handling and shipping. Familiarizing on your own with the components, such as the tensioning mechanism and sealing method, can aid you choose the right machine for your company

Secret Advantages of Making Use Of a Strapping Device

When you purchase a strapping device, you're not simply improving your product packaging process; you're likewise improving performance and integrity. These makers permit quicker strapping, lowering manual labor and reducing the risk of errors. You'll discover a marked decrease in time invested in product packaging, allowing your group to concentrate on various other essential tasks.Moreover, strapping makers supply consistent stress and safe and secure plans, which assists avoid damage throughout transportation. This dependability results in fewer returns and enhanced customer complete satisfaction. Additionally, using a strapping maker can conserve you money in the future by minimizing product waste and decreasing labor costs.Lastly, they're flexible adequate to manage various bundle sizes and materials, making them a useful possession in any type of operation. Accepting a strapping machine means you're purchasing an extra structured, reliable, and reliable technique to product packaging.

Sorts Of Strapping Machines Available

You have actually obtained choices when it comes to strapping devices. You can choose in between hands-on strapping equipments for hands-on control or automated strapping systems for efficiency. Each type has its very own benefits, making it essential to choose the appropriate one for your requirements.

Guidebook Strapping Machines

Numerous product packaging solutions exist, hands-on strapping makers stand out for their simpleness and performance. These machines are perfect for small to medium-sized operations where mobility and adaptability are crucial. You'll locate them very easy to make use of, needing very little training. With a hand-operated strapping maker, you can promptly secure packages utilizing polypropylene or polyester bands, ensuring your products remain undamaged throughout shipping.They offer a cost-effective service without giving up top quality, making them suitable for organizations on a budget plan. Plus, hand-operated strapping makers are compact and can fit in tight spaces, allowing you to improve your operations. Whether you're in a storage facility or a small workshop, these equipments can significantly improve your product packaging procedure, making your operations extra reliable and trustworthy.

Automatic Strapping Equipments

Have you taken into consideration exactly how automatic strapping systems can revolutionize your packaging procedures? These devices provide efficiency and precision that hands-on techniques merely can't match. With choices like completely automatic, semi-automatic, and high-speed strapping systems, you can pick the best suitable for your production requirements. Totally automatic systems streamline the whole process, requiring marginal driver treatment. Semi-automatic makers, while still effective, permit a little bit much more control. High-speed systems satisfy high-volume procedures, ensuring quick and reliable strapping. By incorporating these systems, you'll not just decrease labor costs yet also enhance product packaging high quality. Claim goodbye to irregular strapping and hi to consistent, protected bundles that boost your operational efficiency and rate. It's time to step up your video game with automatic strapping services!

Variables to Take Into Consideration When Choosing a Strapping Maker

Selecting the appropriate strapping device can substantially enhance your packaging effectiveness, so it's crucial to take into account several vital elements before deciding. Initially, consider the kind of products you'll be strapping. Different makers are developed for steel, paper, or plastic strapping, so select one that fulfills your needs.Next, think of the speed and volume of your operations - Strapping Machine. If you're collaborating with high volumes, an automatic strapping equipment may be a lot more ideal, while a manual alternative could be sufficient for smaller tasks.Don' t fail to remember concerning the machine's size and impact. Ensure it fits your office without hindering movement.Additionally, search for attributes like flexible stress and sealing approaches to promote versatility. Review your budget plan, stabilizing in advance expenses versus long-lasting efficiency gains. By thinking about these elements, you'll make a more enlightened option that lines up with your operational goals

How to Incorporate a Strapping Device Into Your Operations

To successfully incorporate a strapping machine right into your process, beginning by reviewing your functional requirements. This aids assure the maker fits perfectly into your existing procedures. When that's established, reliable staff training will be crucial to optimizing its efficiency and efficiency.

Assessing Functional Needs

Integrating a strapping equipment into your process can significantly enhance effectiveness and performance. Initially, examine your existing product packaging procedure. Determine bottlenecks where hand-operated strapping reduces you down. Take into consideration the quantity of items you deal with day-to-day and the specific needs for safeguarding those items. Evaluate the physical room offered for the maker to guarantee it fits flawlessly into your operation. Next off, determine the kinds of materials you make use of for strapping, as the equipment should fit them. It's also necessary to assume regarding how the maker will certainly interact with existing tools and process. By recognizing these operational needs, you can pick the best strapping maker that lines up with your objectives, inevitably leading to smoother processes and improved outcome.

Educating Staff Successfully

While the introduction of a strapping device can simplify your process, reliable training for your staff is necessary to optimize its benefits. Begin by supplying hands-on demos to acquaint every person with the machine's attributes and functions. Encourage your team to ask inquiries and share their problems. Develop an user-friendly guidebook or quick-reference overview to enhance training and function as a resource. Set up normal refresher programs to keep abilities sharp and deal with any kind of updates or changes. In addition, appoint a coach or knowledgeable driver to support brand-new employee as they adapt. By buying your team's training, you'll not just boost their confidence yet additionally improve performance, ensuring the strapping maker becomes an indispensable part of your procedures.

Upkeep Tips for Optimal Strapping Device Performance

Preserving your strapping maker is essential for ensuring constant performance and durability. Beginning by consistently checking and tightening up any loosened bolts or screws to stop resonances that can create wear with time. Clean the equipment daily, removing dust and particles that can impact its efficiency. Lube moving parts as advised in the producer's manual, making certain smooth operation and minimizing friction.Monitor the strapping stress and adjust it according to your product specifications, as incorrect tension can result in product damage or lost materials. Strapping Machine. Additionally, check the strapping product for any kind of indications of wear or damage, replacing it as required to avoid disruptions in have a peek here your workflow.Finally, timetable regular expert maintenance to capture prospective problems prior to they end up being significant issues. By adhering to these maintenance pointers, you'll keep your strapping maker running efficiently, boosting your operations and lengthening its life-span

Real-World Success Stories of Strapping Machine Execution

After ensuring your strapping machine runs successfully, it's time to check out how organizations have actually effectively harnessed this technology. Take, as an example, a product packaging business that dealt with irregular strapping. After carrying out a modern-day strapping equipment, they saw a 30% increase in throughput and a substantial decrease in product waste.In one more circumstances, a furniture maker made use of strapping makers to protect products for shipping. This not just quickened their packing process yet additionally minimized damages throughout transportation, causing better customers.Similarly, a shopping business integrated strapping machines into their procedures, permitting them to successfully bundle items and minimize labor costs.These success tales highlight how spending in a strapping equipment can substantially improve your functional effectiveness, cut prices, and improve customer complete satisfaction. By picking up from these instances, you can better picture exactly how this innovation can transform your own service procedures.

Regularly Asked Concerns

Can a Strapping Maker Take Care Of Different Materials and Sizes?

Yes, a strapping equipment can deal with different materials and sizes. You'll discover models developed to accommodate different band widths and thicknesses, ensuring versatility for your packaging requirements and boosting effectiveness in your procedures.

What Is the Average Life Expectancy of a Strapping Maker?

The average life-span of a strapping device usually ranges from 5 to one decade, depending on usage and maintenance. Routine maintenance and correct care can resource assist you optimize its sturdiness and efficiency with time.

Are There Safety Features in Modern Strapping Machines?

Yes, modern strapping makers included numerous safety functions, like emergency stop switches, protective guards, and sensors that avoid procedure when parts are improperly placed. These enhancements help assure your safety and security while using the equipment.

Just How Much Training Is Needed for Operators?

You'll need marginal training for operators, typically a couple of hours to a number of days, relying on their experience. Many makers come with easy to use interfaces, making it very easy for your team to adjust swiftly.

Can Strapping Machines Be Rented Rather of Bought?

Yes, you can lease strapping machines rather than acquiring them. Leasing usually provides adaptability, decreasing in advance expenses while allowing you to update equipment as needed. It's a wise choice for managing your operational spending plan efficiently. You'll discover that strapping equipments come in different types, including manual, semi-automatic, and totally automated versions, each matched for particular operational needs.Understanding exactly how these makers job is essential for maximizing your operations. When you spend in a strapping device, you're not pop over to this web-site just improving your product packaging process; you're also enhancing performance and dependability. You can select between hand-operated strapping devices for hands-on control or automated strapping systems for effectiveness. If you're functioning with high quantities, an automated strapping maker might be more suitable, while a manual choice could be adequate for smaller tasks.Don' t fail to remember regarding the equipment's size and footprint. After implementing a contemporary strapping equipment, they saw a 30% increase in throughput and a considerable decrease in product waste.In another instance, a furnishings producer utilized strapping machines to secure items for shipping.

Report this page